VPSA (Vacuum Pressure Swing Adsorption) is a non-cryogenic gas separation technology…

… which uses special solids (adsorbents) as molecular sieves to segregate the Nitrogen and Oxygen from the mixture of air.

The process is as follows:

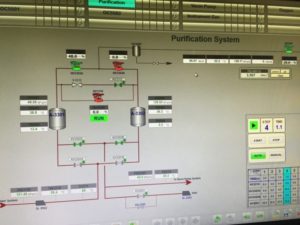

After removing mechanically the impurities from the air by air filter system, the air is compressed in one roots blower and after being cooled down by an air cooler, it is delivered to the adsorber from the bottom. Silencers are installed at inlet and outlet of the blower in order to reduce the noise.

Inside the molecular sieve there are two kinds of adsorbent: The 13X molecular sieve at the bottom used to remove the water, CO2 and hydrocarbon and the LiX molecular sieve at the upper section used to separate the oxygen and nitrogen.

The air moving from the bottom of the adsorber is separated by water and CO2 firstly. Then the dry and clean air go through the LiX molecular sieve layer and nitrogen will be trapped. Most of the oxygen with only small quantity of nitrogen come out from the adsorber in the top, which is our product gas (Oxygen).

When the oxygen purity is reducing, it means the nitrogen adsorptive capacity of LiX molecular sieve achieved the saturation point. The supply of air into the adsorber is stopped and the pressure is reduced by Vacuum Pump. When pressure goes down the Nitrogen in the LiX molecular sieve is released and discharged into atmosphere.

After reaching a due vacuum degree, the Molecular sieve re-obtain the adsorption ability. In order to guarantee continuous oxygen production, two adsorbers in parallel are used. While one is in operation, the second is regenerating. Switching valves are used to control the conversion of two adsorbers.

The production gas will come out from the top of the adsorber and first go into the Oxygen Buffer Tank in order to balance the pressure before being delivered to field.

One characteristic of the VPSA systems provided by Falorni TECH is that they are integrated with the combustion system of the furnace. This means very low specific energy required to produce each single Nm3 of oxygen as the Oxygen pressure requirement is maintained at a minimum value.

The main features of our VPSA systems are:

- Simple architecture

- Low operating cost

- High efficiency

- Low energy requirement

- Up to 95% purity

- From 200 up to 2.000 Nm3/h

- Tailored solutions

Related arguments: