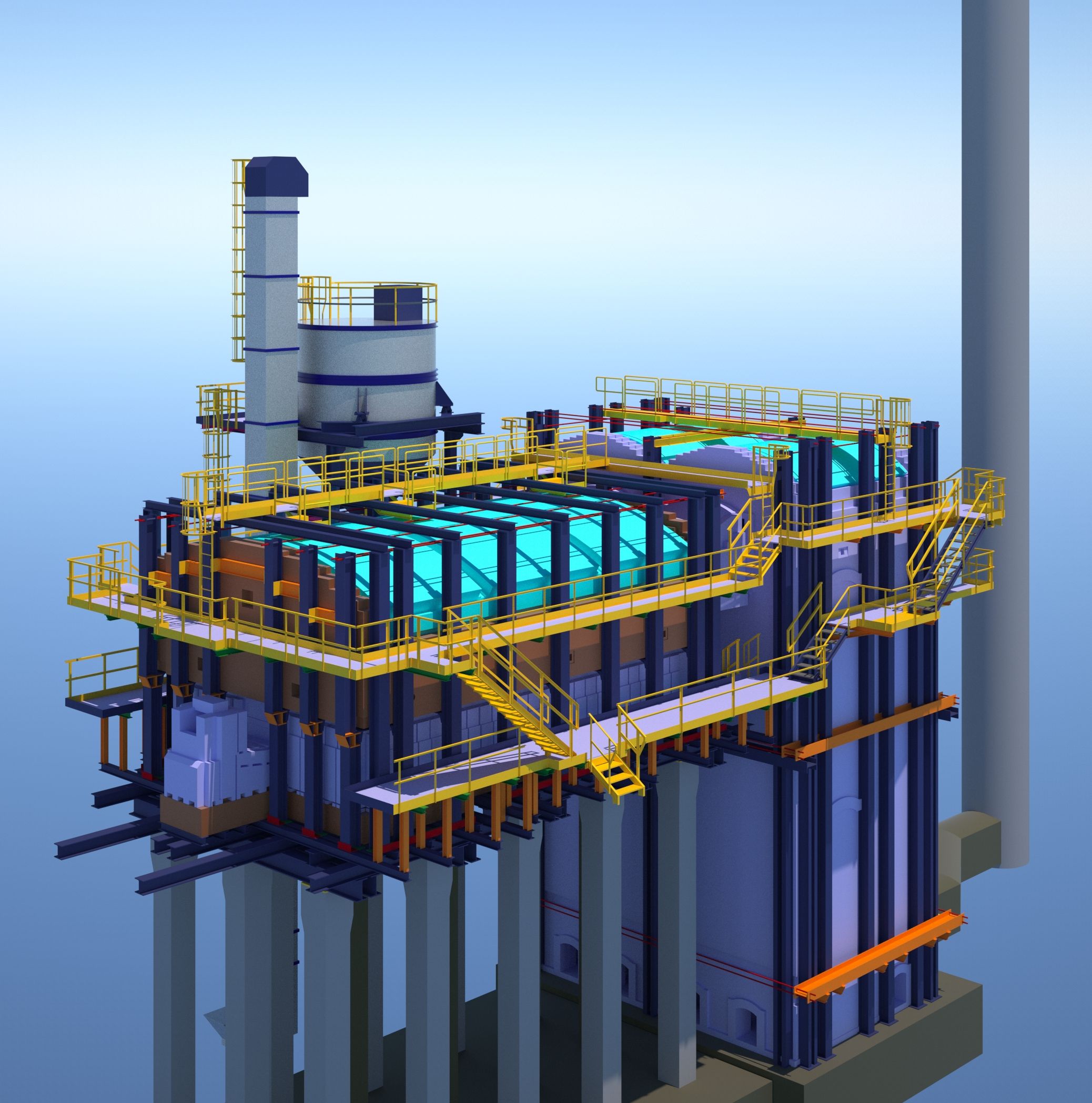

In an end-port regenerative type furnace, the heating is provided by the combustion of the fuel injected through burners installed under the exhaust gas/inlet air-port and the hot combustion air

The combustion air, before being transferred into the combustion chamber through the ports, is heated-up at a high temperature inside the regenerator system which is made of two towers made of special bricks (checkers) realized with high resistant refractory materials. Inside the regenerators, the exhaust gases and cold air are alternatively and separately forced to flow respectively downward and upward. The system works alternating periodically the cycle of the regenerators: in one cycle (one regenerator is heated by hot exhaust gases and the second regenerator is cooled by cold combustion air).

Due to these characteristics, the hot air temperature can reach values up to and beyond 1.300°C depending on furnace size, design, materials, etc. thus granting a high overall energy efficiency to the furnace.

In return, the regenerative furnace is constantly working under severe thermal, chemical, and mechanical conditions, and therefore an appropriate design and choice of materials are needed in order to guarantee the best results in performance reliability and lifespan.

The end port regenerative furnace is the most popular glass furnace for the manufacturing of tableware and container glass like glass bottles or glass jars in white and colored glass.

The main features of a regenerative furnace are:

- Low energy consumption and cost

- High specific pull (tpd/m2)

- Reliable technology

- Good flexibility to pull variation

- Easy operation

Our regenerative furnaces can produce glass in the range from 40 ton/day up to 500 ton/day with or without boosting systems.

Type of glass

- Soda-lime

- Crystalline

- Low boron borosilicate

Fields of application

- Container glass

- Tableware

- Kitchenware

- Pharmaceutical

- Sodium Silicate

Related arguments

- Natural Gas heating systems

- HFO heating systems

- Backup systems

- Underport burners

- scoop type batch chargers

- oscillating tray type batch chargers

- Glass level

- Bubbling system

- Electric booster

- Tank and throat cooling

- Control cabinets

- SCADA supervision systems

- Air/gas reversal system

- Damper valves

- Chimney ejector

- LN-REGEN heating system

- OXY-SWING system