Oxy-fuel heating is more efficient than the conventional air-fuel because the air contains only 21% of oxygen and the remaining 79% of Nitrogen, a neutral gas that does not contribute to the combustion process

This large volume of Nitrogen entering the furnace is heated by combustion up at high temperature and then is exhausted in the atmosphere. Although the energy from the exhaust can be partly recovered by regenerators or recuperators, the effect on general furnace efficiency is negative.

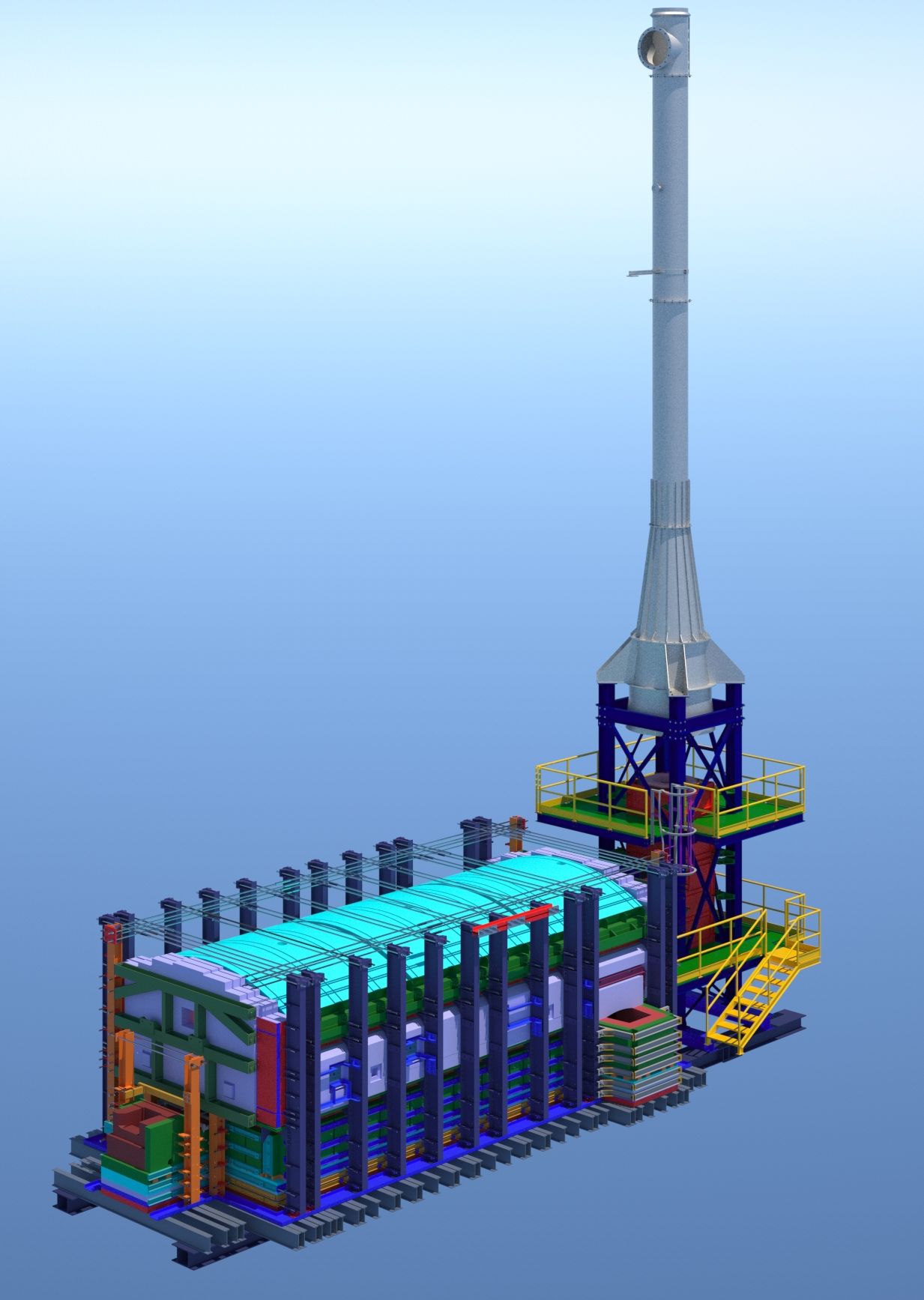

In Oxy-fuel furnaces, only the fuel and the oxygen are introduced in the combustion chamber and the combustion process takes place with a minimum level of Nitrogen and more efficiency.

The Oxy-fuel burners can be installed in a cross-firing configuration which contributes to generating the optimal temperature profile in the glass tank at any furnace load. Moreover, the flame generated has a higher temperature and is more luminous thus granting a higher energy transfer from the flame to the glass.

The level of consumption of an Oxy-Fuel furnace can be up to 25-30% lower than a regenerative furnace and up to 40-50% than a recuperative furnace (depending on size, cullet content, kind of glass, etc.).

But, the key characteristic of oxy-fuel furnace is the attitude to produce low emissions of NOx without any primary measure. From field experience, the level of NOx can be beyond 50% lower than a conventional air-fuel tank of similar size and capacity. This means that an oxygen-fuel furnace can respect the NOx restrictions presently in force in most countries.

The oxy-fuel furnace is used in different production plants and start to be considered the alternative to regenerative furnaces for container and tableware glass.

The main features of Oxy-Fuel furnace are:

- Suitable for any range of production (from 10 up 200 TPD)

- Low investment in infrastructures

- Extremely low emissions

- Low volume of exhaust gases

- Reliable technology

- Excellent flexibility to pull variation

- Easy operation

- Extended lifetime

Type of glass:

- Soda-lime

- Crystalline

- Light borosilicate

- Sodium silicate

Fields of application:

- Container glass

- Tableware

- Kitchenware

- Pharmaceutical

- Glasswool and glass fiber

Related arguments:

- OXY-FUEL heating systems

- OXY-FUEL burners

- Screw type batch chargers

- Scoop type batch chargers

- Oscillating tray-type batch chargers

- Glass level

- Bubbling system

- Electric booster

- Tank and throat cooling

- Control cabinets

- SCADA supervision systems

- Jet Air Damper

- VPSA Oxygen systems