invest in glass manufacturing, especially in the packaging segment is always a good idea. to be successful you must go on a partner with knowledge and expertise. in theory and in practice.

The container glass industry is one of the most dynamic business areas within the world economy, for many reasons. In addition to being 100 % recyclable and can be recycled endlessly without loss in quality or purity, the glass industry has a solid background, the primary raw materials are available in large amounts almost everywhere (low cost of logistic), the demand is linked to food and beverage consumption as well as the pharmacy, cosmetic and perfumery. The competitiveness and technology of the glass industry have reached levels far higher than ever before and, consequently, the initial effort to start an investment in a glass production venture has become more challenging. From our experience, each commercial opportunity must be carried on and not left behind because even the weaker request with apparently not a very solid base could potentially turn into real project execution and realization. Listening to questions, understanding problems, processing data, analyzing frameworks, and fulfilling needs, are the leading inspirations moving our salespeople and engineers when facing new projects and interacting with potential customers.

THE OPPORTUNITY ENGINEERING

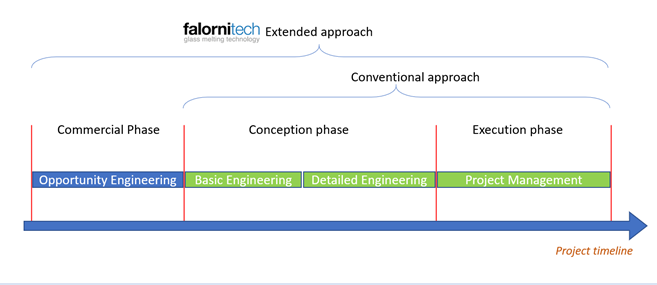

This very preliminary engineering phase, which remains embedded within the frames of the commercial phase of the project and not in the executive phase, is called “Opportunity Engineering”. During this exploratory phase, we propose to evaluate the feasible project path and to find ways of selecting only those where the engineering can have a chance to capture advantages and slice out disadvantages.

Opportunity Engineering is aimed to fuel projects and to enhance the potentiality to make them happen.

Opportunity Engineering is divided into schematic phases

- Preliminary technical study.

A comparison among alternative technologies is carried out to find out the technical solution more suitable to attain the project target both from a practical and economic point of view. As a result, the Investor receives one objective tool to evaluate the technical development and project implementation. With this technical preliminary study, all the critical factors of the project are explored. The privileged guidelines are identified by analyzing:

- Raw material availability and cost

- Melting technologies comparison

- Environmental factors (energy cost, fuel cost, availability of resources, etc.)

- Human factors (manpower cost and skills of personnel)

- Production cost analysis

- Payback

- Project schedule

- Prefeasibility study.

It is carried out by a skilled crew that works using a dedicated and reliable tool that elaborates environmental parameters (market demand, production cost, market price, etc.) in compliance with an economic and financial methodology similar to a Feasibility Study. The aim is to give potential investors the basic information they need to greenlight a project or choose between technologies (size, target production, etc.). An investor will know, with large advance, the main financial index of the project (EBIDTA, Pay Back, NPV, etc.).

- Light 3D modelling.

A three-dimensional plant model is executed starting from the results of the preliminary technical study. The aim is to provide a more exhaustive evaluation of the CAPEX effort to the Investor by showing realistic modelling of the production premises which takes into account, where available, environmental boundary conditions, morphological characteristics and size of the land, etc. Light 3D modelling is an option well appreciated by potential Investors and it is a complimentary service on which Falorni Tech has invested big resources in terms of time and personnel creating a database of plant models and project patterns that is unique in its kind.